No animals needed: How a NY-based company is rethinking leather

Small business unveils vegan leather used in luxury products

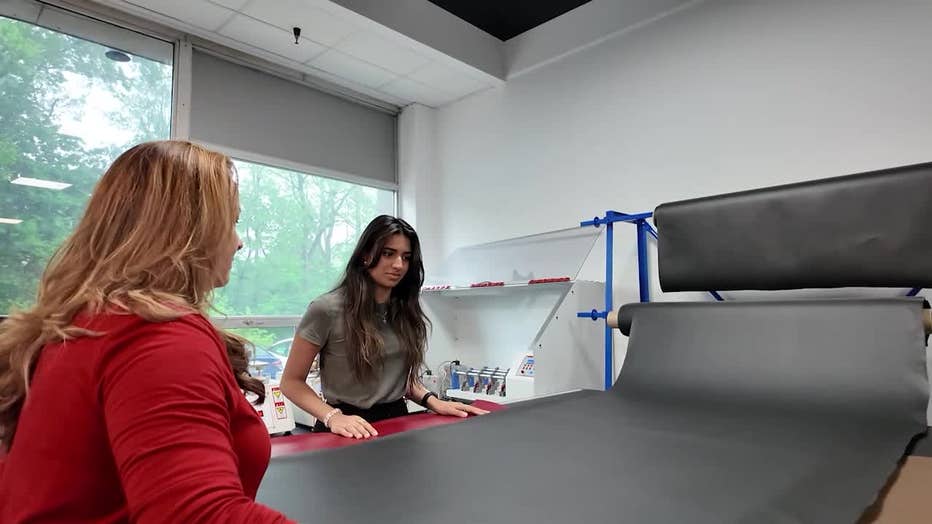

This small company based in White Plains, NY is turning seeds into leather used in luxury cars and fashion. Dan Bowens from FOX 5 NY reports.

NEW YORK - There’s an unmistakable indulgence in fine leather – the texture, the strength, and the timeless elegance. At Uncaged Innovations, they’ve captured all of that – without using animals.

The feel of leather, without the sacrifice

"We’re just evolving an industry," says co-founder Stephanie Downs. "With a different technology."

Local perspective:

From their lab in White Plains, New York, the company produces premium bio-based leather sheets made from wheat, soy, corn, and rice.

Each sheet is crafted using patented technology that reinforces the plant proteins for strength and flexibility – then textured, pigmented and finished to feel every bit as luxurious as traditional leather.

Made in New York, designed for the world

Dig deeper:

Every sheet is carefully crafted at their facility and later produced in mass at a location upstate – but what happens next is a global collaboration. The design, application and final products are brought to life through partnerships with 10 boutique brands around the world – from custom sneakers to handbags, dog collars to smartwatch bands and the interior leather of automobiles.

Big-name brands are paying attention: Ferrari, Aston Martin and H&M have all expressed interest in Uncaged’s material. InMotion Ventures, the investment arm of JLR (Jaguar Land Rover), was also one of the early financial backers. Many brands are reaching out because they want to become more sustainable, while still maintaining luxury quality standards for their products.

"Most of what’s in our pipeline is brands contacting us," Downs says. "It’s surreal."

A material with a mission

What they're saying:

Uncaged was founded by Stephanie Downs, an entrepreneur driven by animal welfare, and Dr. Xiaokun Wang, a biomedical engineer who previously developed corneal implants using biomaterials.

"She invented a way to make human corneal implants out of biomaterials," Downs said.

That molecular research helped Dr. Wang crack the code – mimicking the structure of leather using wheat, soy, corn, and rice – creating a product they call Elevate.

"No flaws. No cruelty. Much lower environmental impact. No animals involved. Everything is vegan, bio-based, and biodegradable."

What sets Elevate apart?

- Scalability: Unlike cactus or mushroom leather, Elevate is designed to scale – meeting high production demands without sacrificing quality.

- Durability: Tested for abrasion, flexing, humidity and temperature, it meets industry standards for fashion and automotive use.

- Price point: Comparable to traditional leather – meaning going sustainable doesn’t mean paying more.

- Environmental impact: Bio-based and eventually biodegradable, it offers a lower carbon footprint than animal or plastic-based leathers.

- Crafting premium materials, without using animal skin.

A new chapter in New York’s leather legacy

New York was once a powerhouse in leather production. Upstate towns like Gloversville in Fulton County earned global recognition – once considered the glove-making capital of the world.

But over time, strict regulations and the rise of cheaper international labor caused the industry to fade. Now, Downs sees an opportunity to reclaim part of that legacy – this time with innovation and sustainability at its core.

"I love the idea of bringing leather manufacturing back to America – back to New York – in a clean way," she says.